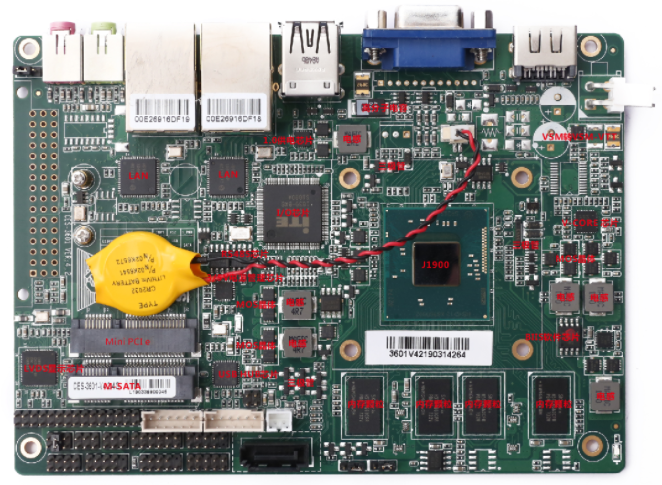

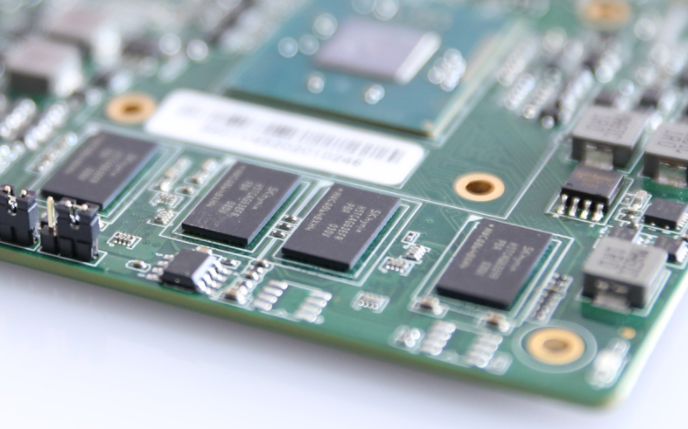

Industrial motherboards are largely similar to commercial office motherboards. The three major components on the motherboard are processors, memory, and hard drives in almost the same form. Industrial motherboards carry the two major flows of current and data. The processor plays a vital role in the computer. Therefore, the quality of the electronic material for the processor directly affects the stability and safety of the whole machine. Many people do not understand why the price of industrial motherboards is so expensive? Then we will explain to you the electronic material composition of the industrial motherboard from HMIvision. You may be able to have a better understanding.

The number of PCB layers of the industrial motherboard:

The quality of the motherboard is determined by the motherboard’s power supply, work materials, PCB, and design. Commercial motherboards generally have a 4-layer design or a 6-layer design, that is, the main signal layer, ground layer, power layer, secondary signal layer, auxiliary power layer, and the medium signal layer.

HMIvision uses a 10-layer PCB board. In addition to the main signal layer, ground layer, power layer, sub-signal layer, auxiliary power layer, and intermediate signal layer, in order to enhance the performance stability of the industrial computer, the design will add one more of main signal layer, ground layer, power layer, and sub-signal layer.

PCB board is an important carrier of industrial motherboard integrated circuits. Although the layers of the PCB motherboard are not the better, the layers of PCB are more, in terms of stability, the density of electronic materials, and the integration of wiring.

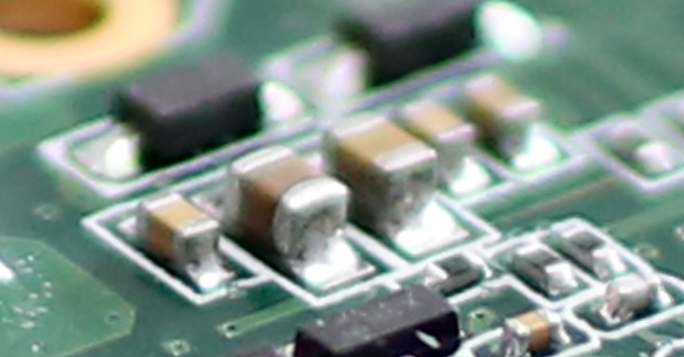

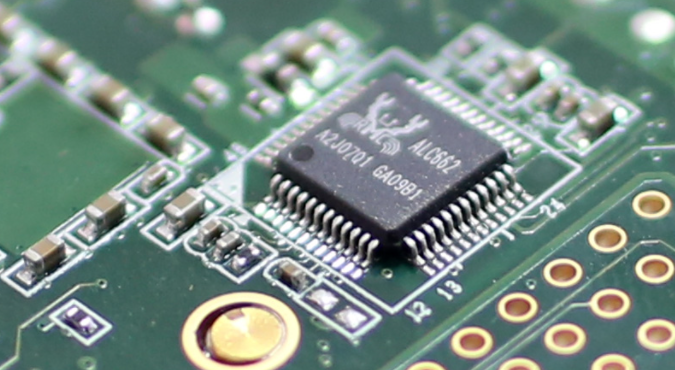

Electronic materials for industrial motherboards-capacitor

Commercial ATX motherboard capacitors are generally large-particle cylindrical capacitors, that is, electrolytic capacitors and solid capacitors.

Electrolytic capacitor:

The metal foil is the positive electrode (aluminum or tantalum), and the metal oxide film (aluminum oxide or tantalum pentoxide) close to the positive electrode is the dielectric. The cathode is made of conductive materials, electrolyte (the electrolyte can be liquid or solid), and other materials Common composition, because the electrolyte is the main part of the cathode, the electrolytic capacitor is named after it. Compared with solid capacitors, the top of electrolytic capacitors will have explosion-proof lines.

Solid capacitors:

Solid aluminum electrolytic capacitors. The biggest difference between it and ordinary capacitors (ie, liquid aluminum electrolytic capacitors) is the use of different dielectric materials. The dielectric material of liquid aluminum capacitors is an electrolyte, while the dielectric material of solid capacitors is a conductive polymer. Since the solid capacitor uses conductive polymer products as the dielectric material, the material will not interact with alumina and will not explode after being energized; at the same time, it is a solid product, so naturally, there is no explosion caused by thermal expansion. Situation. Solid capacitors have excellent characteristics such as environmental protection, low impedance, high and low-temperature stability, high ripple resistance, and high reliability, and are the highest-end products among current electrolytic capacitor products. Compared with electrolytic capacitors, the appearance is smooth with text on the top.

For 3.5-inch industrial motherboards, small capacitor particles (patch solid capacitors) are generally used.

SMD solid capacitors are one type of electrolytic capacitors, especially some products with high-density assembly and small internal space. SMD solid capacitors are resistant to high and low temperatures and are suitable for normal operation in an environment of -50℃ or 100℃.

SMD solid capacitors also have a long life, high insulation resistance, low leakage current, corrosion resistance, and can maintain good performance for a long time. It is one of the first-choice capacitors for 3.5-inch industrial motherboards.

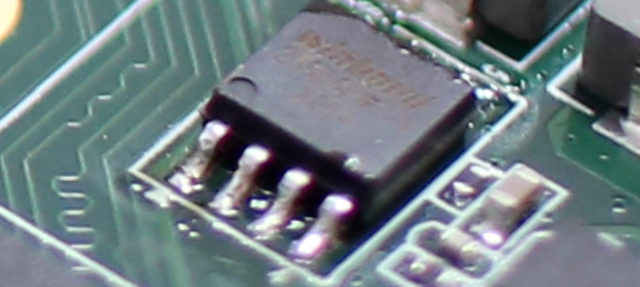

Electronic materials for industrial motherboards-MOS tubes

The MOS tube is a metal-oxide-semiconductor field-effect transistor or metal-insulator-semiconductor. It can be used for detection, rectification, amplification, switching, voltage stabilization, signal modulation, and many other functions. The source and drain of the MOS tube can be reversed, and they are both N-type regions formed in the P-type back gate. In most cases, these two areas are the same, even if the two ends are reversed, it will not affect the performance of the device. Such devices are considered symmetrical.

MOS tube is the most common electronic material in industrial motherboards. Its main purpose is signal amplification, followed by impedance matching and signal conversion.

Electronic materials for industrial motherboards-inductors

Industrial motherboards are relatively complicated in integrated circuits. Most of the inductors are fully enclosed ferrite inductors. Because inductors have the characteristics of energy storage, current flows through the inductors to filter out some high-frequency clutter and then flows through the capacitors to further filter them. The rest of the clutter, so the performance of the inductor fully affects the purity of the power supply of the entire motherboard.

The material used in the high-quality fully enclosed ferrite inductor is a coil with a very thick wire diameter, a new type of magnetic core with high permeability and not easy to saturate, so enough magnetic flux can be obtained without a lot of windings.

The one-phase power supply of the industrial motherboard is composed of 2 or 3 MOS tubes, 2 or 3 solid capacitors, and 1 inductance. Generally, the one-phase power supply can provide 10-30W of electric energy for the processor. The inductance plays a vital filtering role in the processor’s power supply circuit. However, since fully enclosed inductors are currently used on motherboards, we cannot distinguish between the advantages and disadvantages in terms of materials. High-quality industrial motherboards have become the key to the choice of inductor brands.

Electronic materials for industrial motherboards-resistors

Although capacitors and inductors help clean up power clutter, who does the main heavy work when controlling how much voltage each component gets? That’s right, it’s resistance. A resistor, as the name implies, is a resistor that blocks the transmission of current, ensuring that the components of the industrial motherboard will not be damaged due to excessive power.

What is resistance? The resistors we learned in junior high school are generally in the shape of a long colored ring, marking the resistance value, as shown in the above picture. However, the resistance on the industrial motherboard is generally similar to the capacitor particles, and the outside is more low-key, as shown in the above picture. Like a small black + silver square.

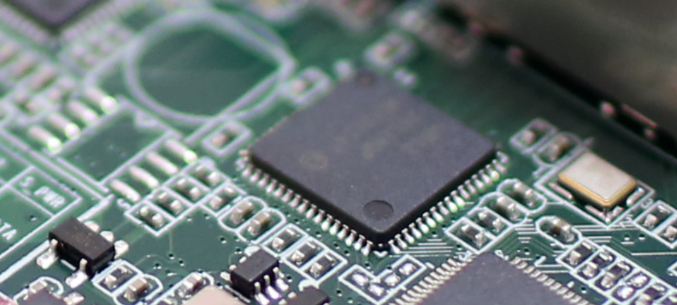

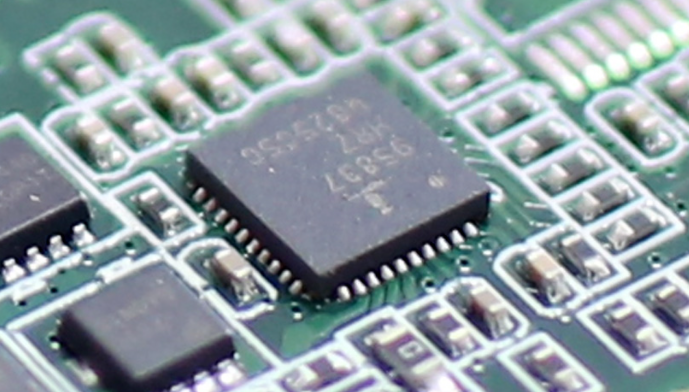

Electronic materials for industrial motherboards-network port controllers

If we only look at the appearance of the industrial motherboard, it is difficult to see the difference in the performance of the network port. The output of the RJ45 form is mostly used in the welded network port of the motherboard. However, the definition of the network port is determined by the internal chip. At present, the network port control system mainly has two major manufacturers, namely, the network port controller chip produced by Intel Corporation and the Realtek network port controller chip of China Taiwan Realtek.

Electronic materials for industrial motherboards-other control chips

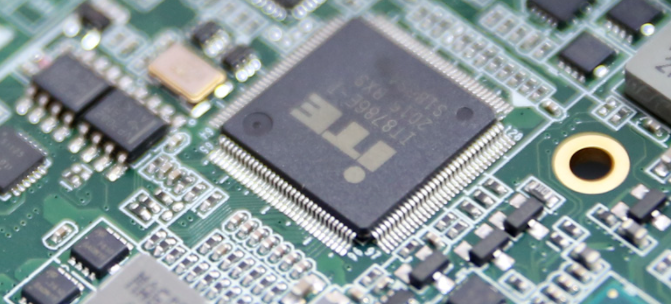

Industrial motherboards have abundant I/O interfaces, so the I/O control chip is also mounted on the motherboard. In addition, other interface chips include LEDs display chip, RS-485 control chip, USB UB chip, BOIS software control chip, V-CORE chip, VSM to VSM-VTT chip, electrical isolation chip, integrated circuit sound card/graphics card, etc.

In general, the electronic materials and manufacturing process level of industrial motherboards determine the quality of motherboards. As industrial products, compared with commercial motherboards, there is no cost advantage in purchasing electronic materials in terms of quantity. In addition, good industrial motherboard manufacturers take into account the stability and reliability of the customer’s application scenarios for their motherboard materials. A few cents in the cost of electronic materials sacrifices quality. Therefore, the overall price of industrial motherboards will be much higher than commercial motherboards.

10.1-inch 1280*800 Industrial Touch Panel PC for Building Security Control (HV-C101B)

Features

● 1. Cordless mainboard design, industrial high-end configuration.

● 2. Rubber ring design on the backside for perfectly embedded mounting.

● 3. Dust-proof, front IP65 waterproof, and shock-proof.

● 4. 9V-36V wide voltage, 6xCOM optional, 3 Pin Phoenix terminal.

● 5. Aluminum alloy shell, fanless design, 7×24 continuous operation.

Categories:

- Accessories44 products

- Camera11 product

- Stainless Steel Keyboard11 product

- VESA Brackets22 products

- Customized Devices3131 products

- Customized Android Touch Tablets77 products

- Customized Touch Monitors33 products

- Customized Touch PCs1111 products

- NFC/RFID/Camera Panel PC1111 products

- Industrial Box PC2424 products

- 4U BOX PC11 product

- Industrial Box/Mini PC2222 products

- IP65 IP67 Waterproof BOX PC11 product

- Industrial PC8888 products

- Weighing Device Panel PC22 products

- 1000nits Panel PC for Kiosk1212 products

- 3mm Bezel Touch PC2020 products

- Android Touch Tablet PC1010 products

- HMI 2nd Industrial Panel PC77 products

- HMI Industrial Panel PC99 products

- IP65/IP67 Waterproof PC2121 products

- Open Frame Touch PC22 products

- Rugged Tablet & Laptop77 products

- Stainless Steel Series2525 products

- Stainless Steel Touch Monitor99 products

- Stainless Steel Touch PC1313 products

- Stainless Steel Android PC33 products

- Touch Screen Monitors112112 products

- 1000nits Monitor for Kiosk1919 products

- 1000nits Monitor for Marine1414 products

- 3mm Bezel Touch Monitor2020 products

- HMI High-end Touch Monitor1414 products

- HMI PLC LCD Monitor11 product

- IP65/IP67 1000nits Monitor3636 products

- Open Frame Touch Monitor1414 products