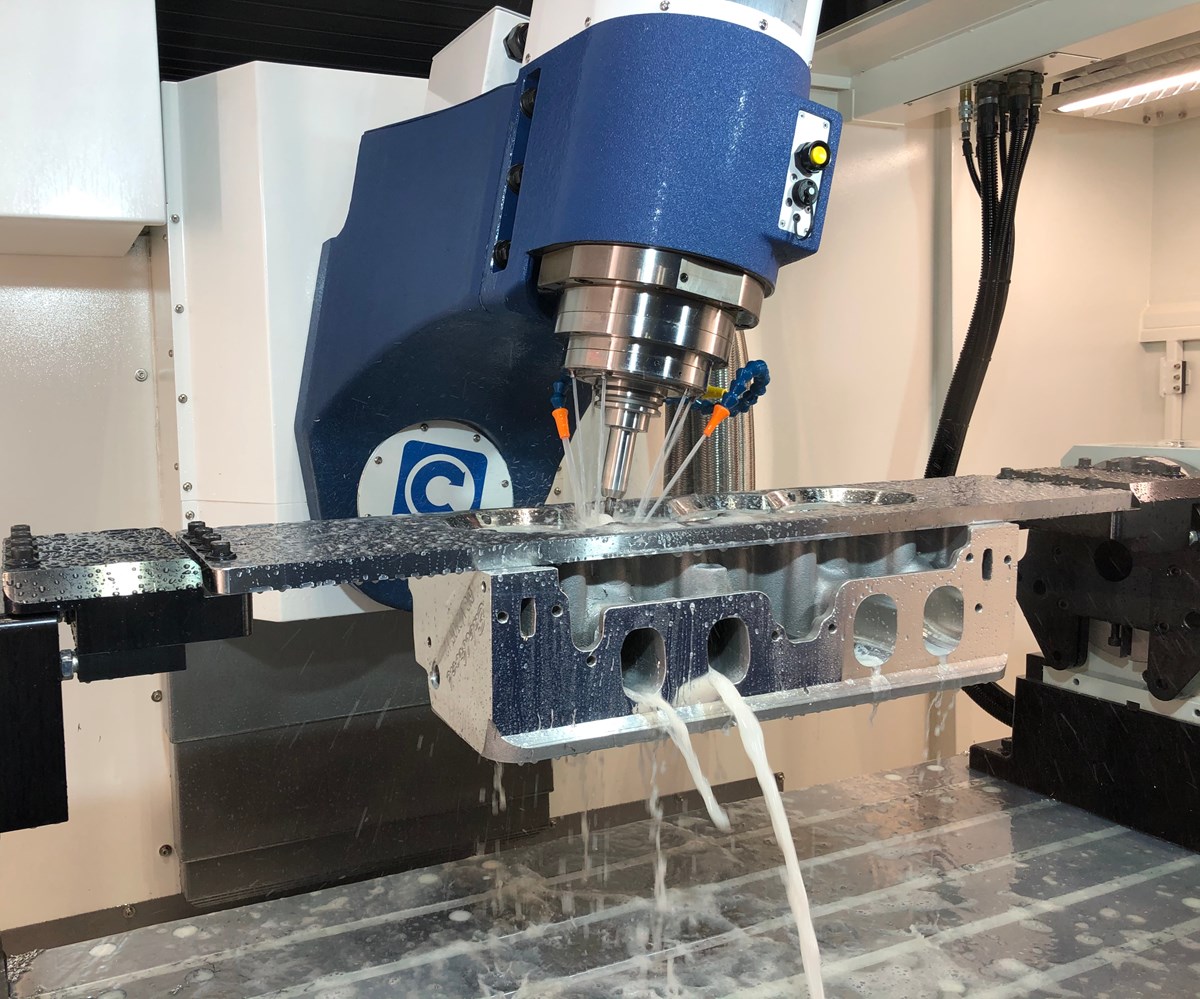

Modern numerical control equipment manufacturing technology is the basis of modern manufacturing. Its development and application have opened up a new era of manufacturing and brought about tremendous changes in the world pattern, especially in aerospace, automobiles, and ships.

The numerical control technology is a core indicator that measures the modernization of a country’s manufacturing industry. It is the development direction to achieve numerical control during production processes. The competition in mechanical manufacturing is actually the competition in the CNC industry.

Tools, as one of the core components of CNC machines, service life and the degree of wear directly affects the accuracy. Therefore, maintenance and monitoring are particularly important. At present, there are two monitoring methods:

1. The detection scheme of installing hardware sensors or probes:

It requires drilling holes in the cutter head, which affects the processing accuracy. In addition, the sensors and probes may be damaged during the processing.

2. Through Software:

With real-time monitoring, prediction of tool life, it is easier to deal with tool changes during the production process, and avoid instrument, products, module damages caused by tool breakage, chipping to maximize the utilization of tool life. Taking effective measures such as sending stop signals, sending tool breaking information, three-color light alarm, etc., to carry out preventive intervention and control in the production process.

This model uses the onboard CPU & memory, with the reinforced hard disk, so that it will not loosen and cause the computer to blackout or shut down under the environment of machine vibration. As a mid-range Intel processor, the J1900 has four cores and four threads, and the main frequency can reach 2.0GHZ, which fully meets the tool data collection and monitoring of machine tools.

With Front IP65 waterproof and dustproof, and the serial port can be customized according to customer requirements. At the same time, the power connector adopts an aviation plug, which is not easy to lose and has high reliability.

With a resistive touch screen to prevent oil stains, It is recommended that customers choose to use resistive screens in oily and dusty environments. Capacitive screens are easily contaminated with oil and mistakenly touched will cause misoperation.

Other Products:

17-inch Industrial Touch Panel PC J1900 4G+64G 1024*768 for Laser Cutter System (HV-C170B)

Features

● 1. Cordless mainboard design, industrial high-end configuration.

● 2. Rubber ring design on the backside for perfectly embedded mounting.

● 3. Dust-proof, front IP65 waterproof, and shock-proof.

● 4. 9V-36V wide voltage, 6xCOM optional, 3 Pin Phoenix terminal.

● 5. Aluminum alloy shell, fanless design, 7×24 continuous operation.

Categories:

- Accessories44 products

- Camera11 product

- Stainless Steel Keyboard11 product

- VESA Brackets22 products

- Customized Devices3131 products

- Customized Android Touch Tablets77 products

- Customized Touch Monitors33 products

- Customized Touch PCs1111 products

- NFC/RFID/Camera Panel PC1111 products

- Industrial Box PC2424 products

- 4U BOX PC11 product

- Industrial Box/Mini PC2222 products

- IP65 IP67 Waterproof BOX PC11 product

- Industrial PC8888 products

- Weighing Device Panel PC22 products

- 1000nits Panel PC for Kiosk1212 products

- 3mm Bezel Touch PC2020 products

- Android Touch Tablet PC1010 products

- HMI 2nd Industrial Panel PC77 products

- HMI Industrial Panel PC99 products

- IP65/IP67 Waterproof PC2121 products

- Open Frame Touch PC22 products

- Rugged Tablet & Laptop77 products

- Stainless Steel Series2525 products

- Stainless Steel Touch Monitor99 products

- Stainless Steel Touch PC1313 products

- Stainless Steel Android PC33 products

- Touch Screen Monitors112112 products

- 1000nits Monitor for Kiosk1919 products

- 1000nits Monitor for Marine1414 products

- 3mm Bezel Touch Monitor2020 products

- HMI High-end Touch Monitor1414 products

- HMI PLC LCD Monitor11 product

- IP65/IP67 1000nits Monitor3636 products

- Open Frame Touch Monitor1414 products